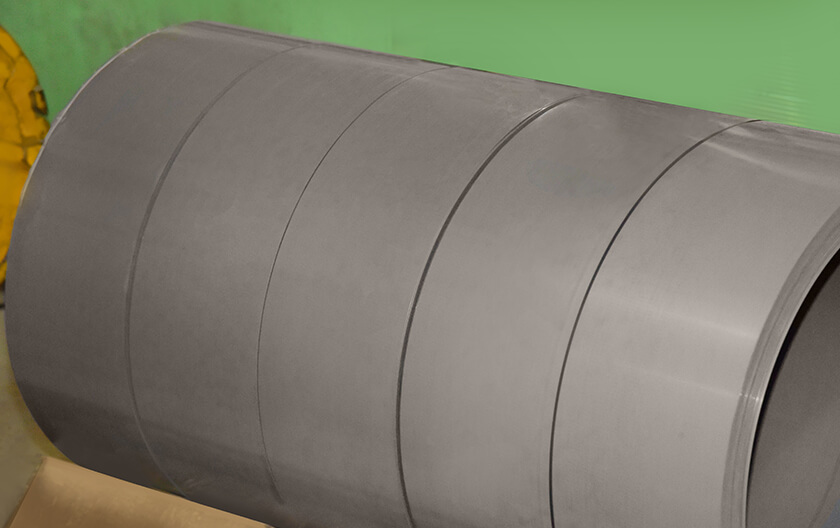

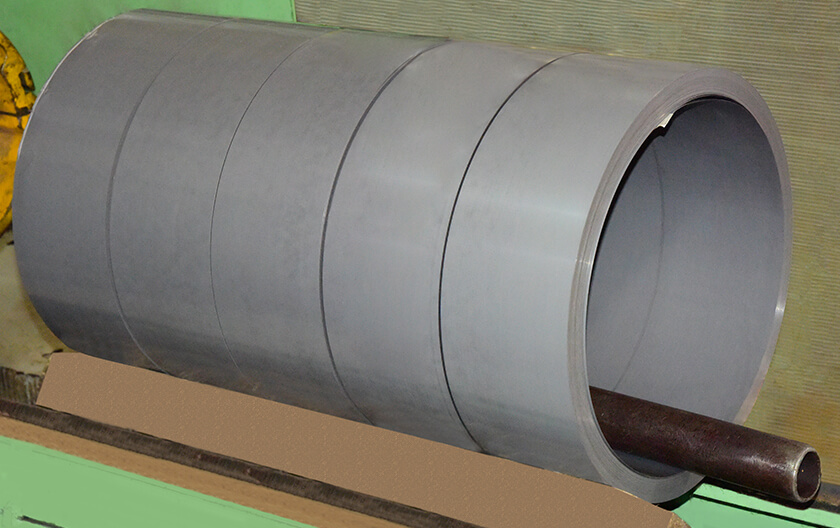

Slit Rolls

Slitting is the first and foremost manufacturing process in order to obtain any type of cut lamination. Indeed, it is the heart of the whole manufacturing process and to ensure it continuous beats, it should be tuned with fine accuracy and high quality standard.

Slitting process is the origin where quality standard starts, and subsequently it is maintained by the different types of cutting process. Quality of the material is always on top priority at Navkar Transcore and thus we stress more on slitting process for better quality in every single process.

Navkar Transcore has the facilities to cut strips from the entire range of CRGO coils used by the Electrical Steel Industry, with high permeability in thickness ranging from 0.18 to 0.35mm.

At Navkar Transcore, we have set up essential quality check-points during slitting process to ensure that the burr level of material is well within the tolerance. The precise slitting process can undoubtedly slit the material without any generation of scrape. (I.e. slitting of a coil of 120 mm in two different 60 mm coils is promising task).