Transformer Lamination

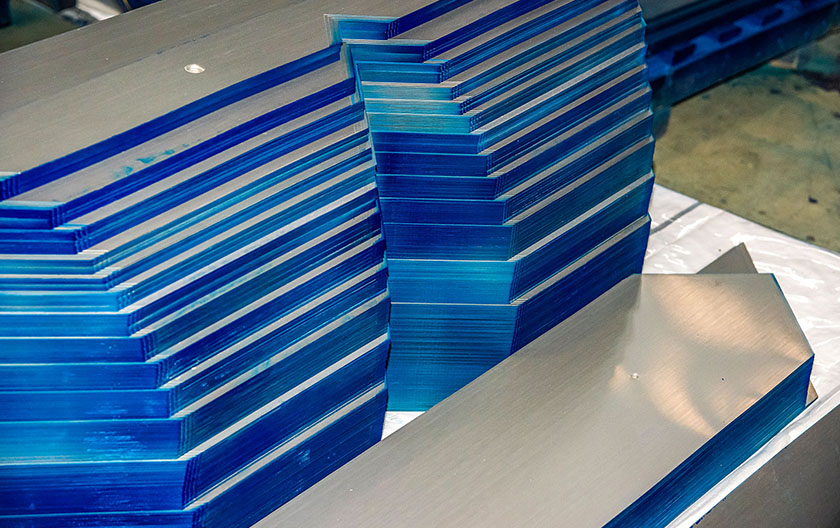

Transformer core lamination for Power & Distribution transformers is manufactured from various grades of Cold Rolled Grain Oriented ( CRGO ) steel. Lamination in various shapes & sizes are slit and cut to required accurate geometrical shapes with 90° & 45° cutting systems. The manufacturing of Cold Rolled Grain Oriented CRGO Quality Lamination involves a high degree precision engineering.

Transformer lamination can be of various sizes for single or three-phase transformers, made with overlap joints or step lap joints (Cross/Longitudinal). They are cut, punched and V-notched in order to fit in a particular transformer by CNC – cut to length line. Cutting, Punching and Notching of different shapes of sheets are possible in width up to 1000 mm and length up to 5500 mm. Navkar Transcore, with its integrated software to convert conventional design to Step lap design, insists transformer manufacturers to opt for Step lap design. Step lap core design enables easier path for flux to travel at the joints and therefore reducing No Load Losses of transformer core by 5 to 8%. Navkar Transcore team also assists in core assembly if required.

In addition to the cutting of the CRGO lamination, Navkar Transcore offers built core, assembled core (Overlap/Steplap joints).

Advantages CRGO Cold Rolled Grain Oriented steel product

The aspect of well-organized material handling is given specific involvement as both the raw materials and finished products are highly sensitive. NTPL has gained expertise in processing CRGO laminations with increased production capacity to cater to client specifications with speed and integrity. This efficiency in production, has earned NTPL a significant ISO 9001 Certification which very few companies obtain in the Lamination industry and which speaks volumes for NTPL. With adequate inventory and skilled staff, the processing cycle has been cut short that facilitates faster outputs.

Quality Control and Checks

NTPL devotedly carries out Lamination Quality Controls and Checks that are established at various levels of the production process. These frequent checks start from manufacturing process to their dispatch. All the results are documented diligently with separate ones for each drawing to increase the effectiveness of particular jobs. Finally, the company has efficient delivery inspectors who conduct inspections of CRGO laminations and only after satisfactory results, permit delivery of products.